Vetrotech’s Würselen Plant Slashes Energy Consumption by 45%

Date:

Continuous Improvement Drives Reductions in Emissions, Energy Demand

When Vetrotech Saint-Gobain moved production of its fire-rated and high-security glass in Germany from the historic Vetrotech Kinon production facility in Aachen to a spacious new plant in Würselen, it set in motion a process for modernizing operations in a way that would move the company closer to its sustainability goals. Today, Vetrotech Saint-Gobain Würselen is innovating not only in how it produces glass but also in how it operates.

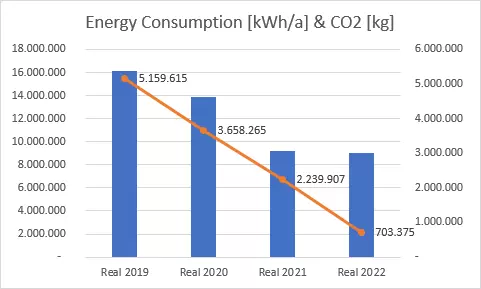

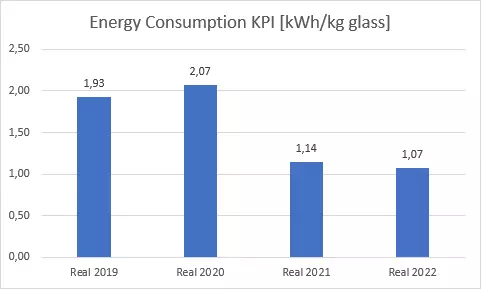

Since the plant opened, it has achieved tremendous strides in reducing its energy consumption per kg of glass cut. This key metric has moved from 1,93 kWh/kg glass cut in 2019 to 1,07 kWh per kg of glass cut in 2022, a reduction of 45%. That equates to a carbon reduction of more than 4,4 million kg of carbon dioxide equivalent.

New measures reduce environmental impact

Simply moving production to Würselen allowed the company to bring a range of processes together under one roof, reducing emissions generated in transporting products for offsite processing or testing. This move also allowed Vetrotech to fully eliminate gas as an energy source for production processes. Since 2023, all production in Würselen has run on 100% green electricity through its purchase of offsite hydroelectric power. The plant is exploring strategies to produce green energy onsite so that it can contribute to the production of renewable energy for the local electric grid.

While the facility was initially constructed featuring a range of energy-efficient systems designed to reduce CO2 emissions, the plant has taken steps to further reduce energy consumption each year. In 2023, two projects in particular promise to significantly reduce energy demand going forward:

-

The team has added an interval timer to the production office’s gas-fueled air conditioning system. Through adjustments to the temperature during working and off hours, the facility is consuming 26.000 kWh less natural gas, reducing its energy demand by approximately 7,9 t/year.

-

The autoclave pressure was optimised, thus reducing the amount of energy used during pressurization without impacting the quality of laminated glass produced.

We’re continuing to innovate in how we protect what’s important

This continuous improvement approach is in line with Vetrotech’s ISO 50001 certification. The standard supports organizations of all kinds in developing a data-driven framework for ensuring continuous progress toward energy-efficiency goals.

This work to continually reduce our environmental impact also aligns with Vetrotech’s commitment to protect what’s important. While Vetrotech has always been on the safe side, our dedication to safety increasingly extends into our environmental responsibility. That’s why we have implemented verifiable footprint-minimizing practices throughout our organization, reinvigorated our innovation focus to develop sustainable products and processes, and publicly declared ambitious net zero carbon goals. It’s why we’ve embraced a leadership role in influencing healthy building policies in countries around the world. And it’s why everything we do is done with full transparency.