How Indian Fire-Rated Glass Manufacturers Ensure Compliance with NBC Fire Safety Norms

Glass isn’t the first thing that comes to mind when you think of fire safety. It shatters. It melts. It gives way.

But not all glass is made to fail under pressure. Fire-rated glass is engineered to do the opposite: hold its ground, block smoke and flames, and create safe escape routes when seconds count.

In high-rises, hospitals, airports, and commercial hubs across India, this invisible layer of protection is making all the difference. But strength alone isn’t enough. It must be proven, tested, certified, and aligned with the National Building Code (NBC) Part-4 of India.

So, how do India's fire-rated glass manufacturers and fire rated door manufacturers turn clear glass into a trusted life-safety solution? Let’s break it down.

What is NBC and why does It Matter?

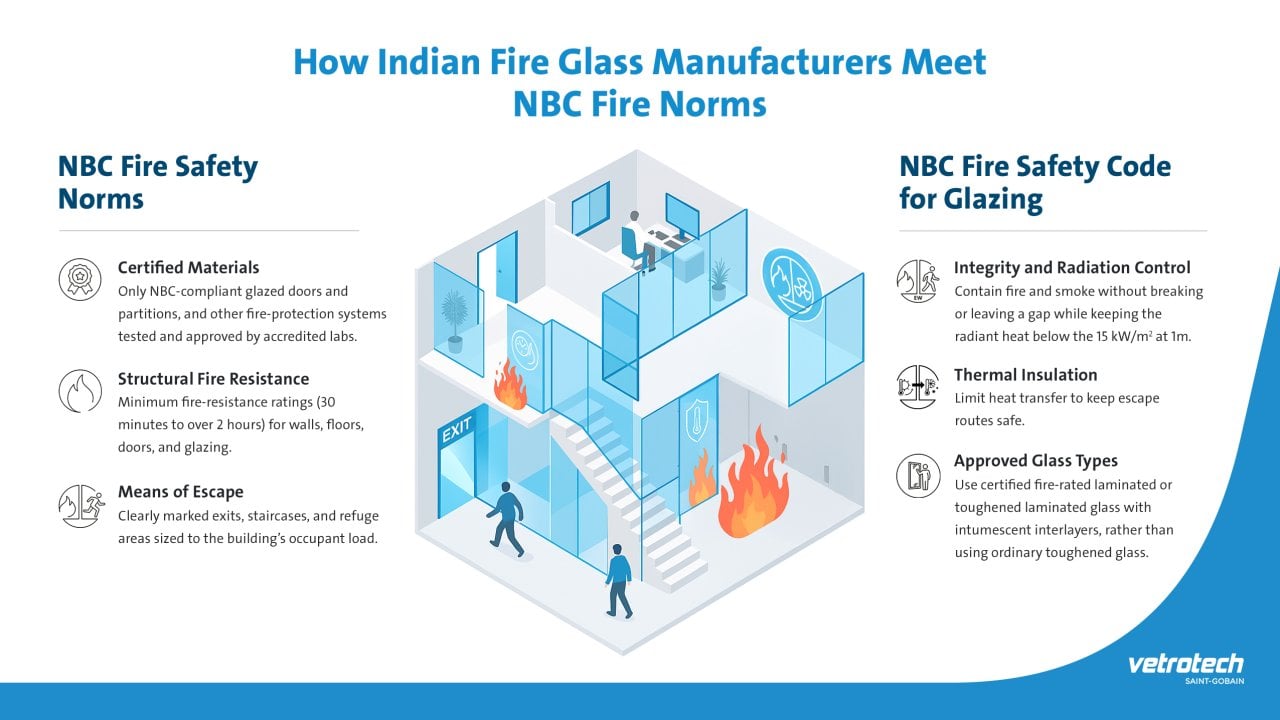

The National Building Code (NBC) of India, established by the Bureau of Indian Standards (BIS), provides guidelines to ensure safe, sustainable, and secure building construction. Among its many sections, Part 4 focuses on fire and life safety, setting strict requirements for how structures should perform in the event of a fire. The Code specifies fire detection & suppression systems and guidelines for passive fire protection that can prevent the spread of fire.

Whether it’s a residential apartment, a hospital, a shopping mall, or an office complex, NBC compliance is critical to protect lives and property. Fire-rated glass, used in doors, partitions, and facades, must be engineered and tested to meet fire rating to specific guidelines.

And that’s where fire-rated door manufacturers step in, with systems that combine compliant materials, robust design, and documented performance.

Key Fire Glass Requirements as per NBC

According to NBC, fire-rated glass must meet criteria for:

- Flame integrity – Containing the spread of fire and smoke and ensuring that the entire system maintains physical integrity

- Thermal insulation – Blocking the transfer of heat

- Radiation control – Reducing the risk of ignition from radiant heat by controlling the heat radiation to less than 15Kw/m2 at the distance of 1m for the rated time

NBC also defines minimum fire-resistance durations for various occupancy types, ranging from 30 minutes to over 2 hours. Compliance also involves:

- Third-party testing and certification

- Proper labelling and traceability

- Installation documentation to prove performance

Manufacturing Process of Fire-Rated Glass in India

Not all fire-rated glass is created equal. The industry offers several varieties:

- Wired glass: Traditional and simple, with metal mesh inside.

- Tempered glass: Heat-treated for strength but limited fire resistance.

- Ceramic glass: Offers excellent fire resistance but is heavier and more expensive.

- Laminated glass with intumescent interlayers: The modern favourite, combining durability with active fire protection.

Among these, laminated glass with intumescent gel is widely preferred. This gel expands when exposed to heat, sealing gaps and blocking smoke and fire, and controls the heat radiation, while the glass on the non-fire side maintains structural integrity.

The Manufacturing Process

Ever wondered how fire-rated glass is made? It’s a precise science. Manufacturing fire-rated glass typically involves:

- Heat treatment/Tempering: Glass sheets are tempered to induce strength and thermal resistance.

- Lamination: Multiple layers of glass are bonded with intumescent interlayers designed to react to fire.

- Curing: The glass sandwich is cured under controlled conditions to ensure perfect bonding.

- Quality checks: Each batch undergoes optical clarity tests, mechanical strength assessments, and fire resistance trials.

Fire-rated glass manufacturers incorporate this meticulous process to ensure the glass performs reliably, not just in the lab, but in real-world emergencies.

How Indian Fire-Rated Glass Manufacturers Ensure NBC Compliance

Leading fire rated door manufacturers in India don’t rely on guesswork. At Vetrotech, every fire-rated glass or system is tested in-house and at internationally accredited third-party labs to meet both Indian and international benchmarks, such as ISI, BS (British Standards), UL (Underwriters Laboratories), and EN (European Norms).

These tests simulate real-world fire conditions and verify fire-rated system compliance for load-bearing capacity, thermal shock resistance, and fire endurance. These tests confirm that the glass meets the NBC’s requirements for flame integrity, insulation, and radiation control, for specified durations.

- Collaboration with Architects and Fire Consultants

Compliance begins at the drawing board. Fire rated door manufacturers work closely with architects and fire safety consultants to specify the right glass systems tailored to each building’s fire zone and occupancy load.

This early collaboration ensures the glass system fits perfectly within the overall fire strategy and NBC guidelines, eliminating costly retrofits or unsafe substitutions later.

-

Collaboration with BIS and NBC Authorities

Indian fire-rated glass manufacturers actively engage with BIS authorities, helping to develop and refine national standards like the NBC and fire testing standards. This ongoing dialogue keeps regulations up to date with the latest technology and real-world needs.

-

Documentation and Traceability

Traceability isn’t just good practice; it’s an BIS requirement. Every certified fire-rated glass carries:

- Clear labelling and marking

- Comprehensive test reports

- Full material traceability

- Certified installation documentation

These documents ensure accountability, transparency, and peace of mind for builders, regulators, and occupants alike.

Challenges Faced by Indian Manufacturers

Regulations are only effective if they’re enforced. Unfortunately, enforcement of NBC norms varies across regions in India, causing confusion and gaps in compliance.

A widespread myth also persists that regular toughened glass offers the same fire protection as certified fire-rated glass. It doesn’t. Toughened glass can shatter when exposed to high heat, whereas fire-rated glass is specifically designed to contain fire and smoke for a high temperature for a designated time.

Fire rated door manufacturers must constantly battle misinformation while also driving awareness and training with the construction ecosystem, like with programs like the VDS Certified Installer Program.

The Way Forward: Building Trust Through Compliance

The future of fire safety in India depends on:

- Stronger awareness and education for developers, architects, and contractors

- Consistent enforcement of NBC fire safety norms

- Continued innovation in fire-rated glass technology

By embracing transparency and rigorous certification, fire-rated glass system manufacturers are building trust and safer buildings today and for years to come.

The Final Layer of Defence: Choosing Code-Compliant Fire-Rated Glass

At Vetrotech, we understand that fire safety is about more than just transparency; it’s about providing reliable protection when it truly counts. That’s why our fire-rated glass systems are designed and tested to meet the stringent requirements of the National Building Code (NBC) of India, ensuring they deliver performance you can trust.

Compliance with NBC norms is a vital responsibility, and we are committed to supporting developers, architects, and safety consultants by offering certified fire-rated glass solutions that integrate seamlessly into every project’s fire safety strategy.

Our Vetrotech Design Solutions (VDS) further enables tailored system designs that align with both regulatory standards and specific building needs.

By combining rigorous testing, collaboration, proper installation of the fire rated system as per test evidence and innovation, we aim to be a dependable partner in safeguarding lives and property because when it comes to fire protection, every second behind the glass matters.