The Role of a Fire Testing Laboratory in Product Development

Fire safety plays an important role in construction industry where fire hazards can have severe consequences. A fire testing laboratory ensures that materials and systems meet stringent safety standards, helping manufacturers create products that can withstand fire hazards. Compliance with national and international regulations isn’t just about meeting requirements but about building safer, more reliable products that protect lives and property.

Understanding the Function of a Fire Testing Laboratory

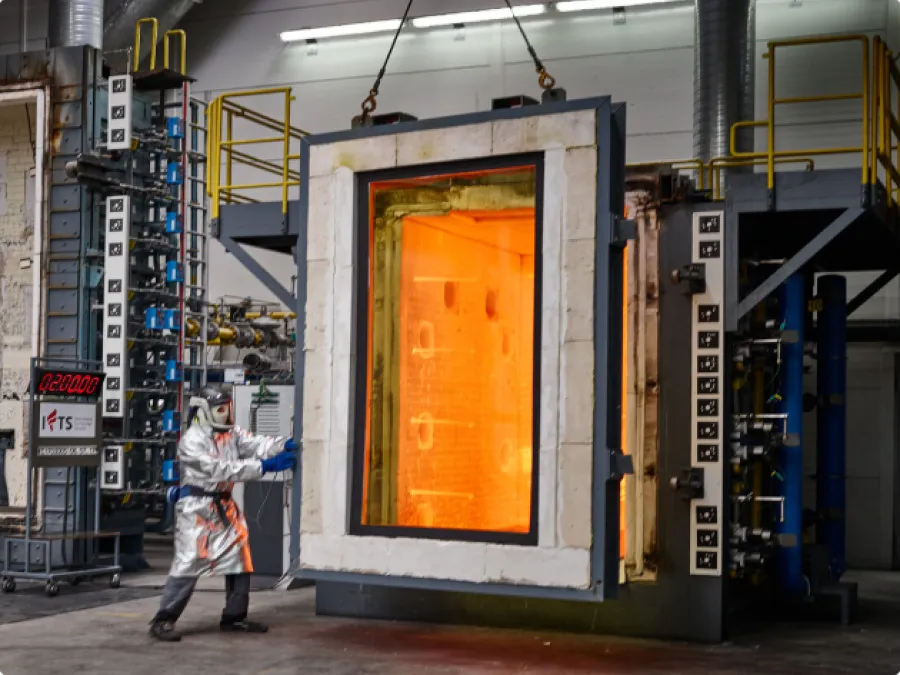

A fire testing laboratory is a third party specialised facility where materials, products, and systems undergo evaluation in accordance with testing standards to assess their behaviour under fire conditions. These laboratories play a crucial role in ensuring fire safety by conducting controlled experiments that simulate real-world fire scenarios.

Types of Fire Tests Conducted

Fire testing laboratories perform a different types of tests like reaction to fire and resistance to fire to evaluate different aspects of fire performance:

-

Flammability and Ignitability Testing: Determines how easily a material catches fire and how quickly flames spread.

-

Fire Resistance and Endurance Testing: Measures how long a product, such as doors, walls, or glazing systems can withstand fire before failing.

-

Smoke and Toxicity Evaluation: Assesses the amount and composition of smoke and toxic gases released during combustion, which is critical for occupant safety.

By generating precise data on fire behaviour, these tests help manufacturers refine their designs, improve material performance, and ensure compliance with safety regulations.

Key Fire Testing Standards and Regulations

Fire safety regulations ensure that materials and products meet strict performance criteria before being used in real-world applications. Fire testing laboratories play a vital role in helping manufacturers comply with these standards efficiently.

Some widely recognised fire testing standards include:

-

EN 1364 & EN 1634: Assess the fire resistance of building components.

-

UL 10B/10C & ASTM E119: Define fire ratings for door assemblies.

-

ISO 834: Establishes international fire-resistance testing guidelines.

By adhering to these standards, manufacturers can enhance product reliability, ensure regulatory approval, and improve overall safety.

How Fire Testing Enhances Product Development

Incorporating fire testing early in product development is essential for ensuring safety, performance, and regulatory compliance with respect to the growing market trends. By subjecting materials and systems to controlled fire conditions, manufacturers can:

-

Identify design flaws early: Detect vulnerabilities before mass production, reducing costly redesigns.

-

Ensure compliance with safety regulations: Meet industry-specific fire safety standards, avoiding legal and certification hurdles.

-

Enhance durability and fire resistance: Improve material performance, ensuring longevity and safety in real-world conditions.

Different industries rely on fire testing laboratories to validate product safety:

-

Construction Industry: Fire-rated doors, facades, and glazing systems undergo rigorous testing to ensure they withstand fire exposure.

-

Automotive Sector: Vehicle interiors and components are assessed for flammability to enhance passenger safety.

-

Electronics and Appliances: Consumer devices are tested for heat resistance and fire hazards to prevent electrical fires.

The Role of Fire Testing in Certification and Compliance

Fire testing plays a crucial role in securing certifications that validate a product’s safety and performance. Without proper testing, fire-rated materials may not meet regulatory requirements, limiting their use in construction, automotive, and other industries.

Accredited fire testing laboratories ensure that products undergo rigorous evaluations under controlled conditions, producing reliable results that regulatory bodies trust. This process not only helps manufacturers achieve compliance but also strengthens their credibility in the market. Certified products inspire confidence among architects, builders, and end-users, ensuring that fire safety standards are met without compromise.

Why Architects, Channel Partners, and Occupants Should Choose Manufacturers Who Test in the Right Laboratory

Fire safety is not just a regulatory requirement but a fundamental necessity in building design and product selection. For architects, channel partners, and occupants, choosing manufacturers that rigorously test their products in accredited fire testing laboratories ensures safety, compliance, and long-term reliability.

1. Verified Safety and Compliance

Products that undergo fire testing in certified laboratories meet established national and international fire safety standards. This ensures regulatory compliance, reducing liability risks for architects and builders. Fire-rated materials that pass these stringent tests provide a reliable line of defense, ensuring occupants’ safety in real-world fire scenarios.

2. Reliable Performance

Fire-resistant materials and systems must perform as expected during an actual fire. Certified fire testing validates a product’s ability to withstand standard conditions, ensuring that fire doors, glazing systems, and structural components function effectively when needed most. For architects and developers, this guarantees that the materials used align with building safety regulations.

3. Stringent Testing Processes

Accredited laboratories adhere to standard testing protocols set by the fire testing standards to account for challenges such as material variability, real-life fire condition replication, and evolving fire safety standards. Their adherence to international guidelines ensures consistency and accuracy in test results. This ensures that manufacturers’ products undergo rigorous testing under the most demanding conditions, verifying their reliability and compliance with safety standards.

4. Long-Term Trust and Credibility

Choosing manufacturers who invest in high-quality fire testing strengthens trust in their products. When channel partners and occupants opt for fire-rated materials from reputable sources, they ensure that buildings are equipped with materials that have been rigorously evaluated for safety and performance. This commitment to quality enhances credibility and reduces the risk of unforeseen fire hazards.

Why Continuous Fire Testing Is Essential for Product Improvement

Fire safety is not only a one-time assessment; it requires continuous evaluation to keep up with evolving regulations, new materials, and real-world fire scenarios. Ongoing fire testing ensures that fire-rated products maintain their reliability throughout their life cycle.

Regular testing helps manufacturers adapt to updated safety standards, ensuring that their products continue to meet compliance requirements. It also provides critical insights into product performance, allowing for design refinements that enhance fire resistance and durability.

By integrating periodic fire testing into product development, manufacturers not only uphold safety standards but also build long-term trust with architects, builders, and occupants who rely on their fire-rated solutions.

Ensuring Safety and Compliance Through Fire Testing

Fire testing laboratories are crucial in verifying that fire-rated products meet the highest safety standards. Their rigorous testing processes provide manufacturers with critical data to refine designs, enhance fire resistance, and ensure compliance with evolving regulations.

As a global leader in fire-resistant glazing, Vetrotech is committed to continuous testing and certification, ensuring its solutions provide superior protection without compromising design or functionality. By integrating extensively tested and certified fire-rated glazing, architects, builders, and developers can create safer environments that meet stringent fire safety requirements.