How to Enhance Industrial Safety with Certified Glass Solutions

Industrial safety today goes beyond helmets and emergency drills, the materials and structural elements within a facility are crucial in protecting both personnel and equipment.

Certified glass solutions, such as laminated and toughened glass, provide protection against heat, human impact, and operational hazards while maintaining clear visibility and smooth workflow. Proper selection of glass also supports fire and safety strategies and aligns with local regulations.

Here’s a detailed look at how certified glass solutions enhance industrial safety.

What is Certified Safety Glass?

Certified safety glass is specially engineered and tested to meet stringent standards for impact resistance, thermal tolerance, and structural safety. Think of it as a reinforced, smarter version of ordinary glass, designed to meet industrial safety requirements while protecting people and assets.

-

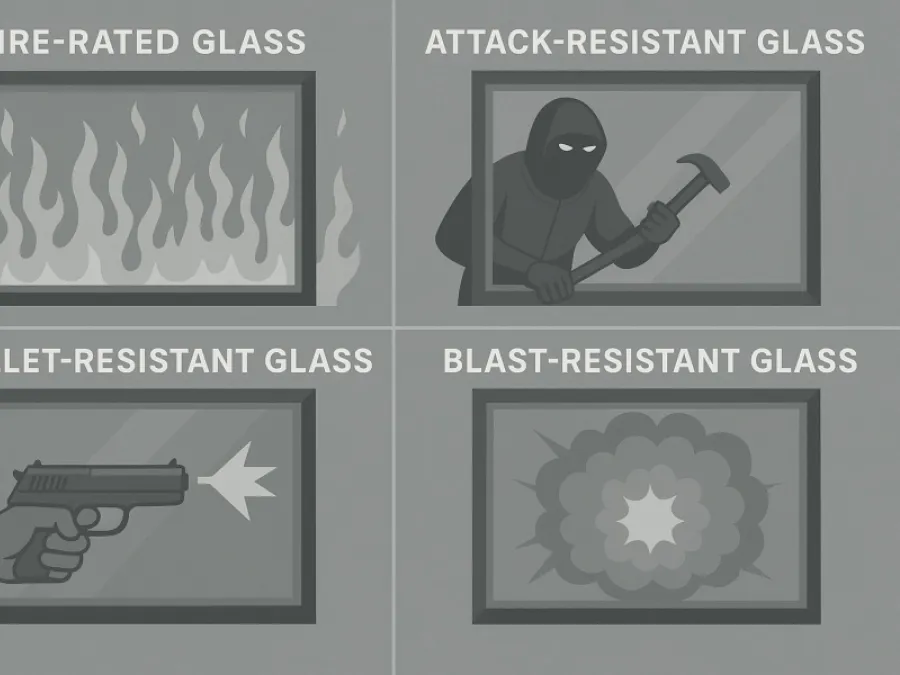

Fire-Rated Glass: Capable of withstanding heat and flames for extended periods, providing essential support for fire and safety protocols in factories and warehouses.

-

Attack-Resistant Glass: Laminated glass with multiple interlayers to resist strikes from tools or accidental impacts without shattering, ideal for protecting high-risk operational zones.

-

Bullet-Resistant Glass: Comprising multiple high-pressure laminated layers, this glass maintains clarity while preventing penetration, suitable for sensitive areas requiring additional protection.

-

Blast-Resistant Glass: Multi-layered laminated glass designed to absorb pressure waves from explosions, essential for chemical plants, refineries, and other industrial facilities.

All these solutions comply with international safety standards and industrial safety requirements, ensuring effective protection without compromising operational visibility.

Where Industries Need Certified Glass the Most

Industrial safety measures aim to protect workers and assets while minimizing operational risk. Different zones within a facility demand different levels of protection:

Fire-Risk Areas

-

Boiler rooms, turbine halls, and power stations benefit from fire-rated glass that can block heat and smoke while allowing supervisors to monitor processes safely.

-

Chemical storage rooms require glass that can withstand high temperatures, reinforcing fire and safety practices.

Machinery and Production Areas

-

Manufacturing floors with heavy machinery need laminated and toughened glass to prevent accidents caused by flying debris or falling tools.

-

Robotic and automated sections benefit from transparent barriers that allow safe monitoring while protecting personnel.

Laboratories and Testing Rooms

-

Quality control labs require durable glass that maintains sterile conditions while offering visibility.

-

Chemical testing areas use impact-resistant glass that remains stable under chemical exposure and pressure changes.

Noisy Production Zones

-

Packaging, bottling, and textile lines generate significant noise. Impact-resistant glass can reduce sound while maintaining visibility and safety.

-

Some glass types can combine noise reduction with fire and safety features for multi-functional protection.

Temperature-Controlled Zones

-

Cold storage and high-temperature areas need laminated and toughened glass that resists thermal stress without cracking.

Control and Supervision Rooms

-

Supervision areas for critical processes require blast-resistant or bullet-resistant glass, providing maximum protection while maintaining complete visibility.

Industries That Need Certified Glass Most

Different industries face unique challenges and understanding them helps us identify where certified glass solutions matter the most. Here's a comprehensive overview:

|

Industry |

Glass Type(s) Required |

Regulation/Standard |

Specific Areas |

Recommended Vetrotech Glass |

|

Chemical Industry |

Fire-rated glass, blast-resistant glass |

Chemical Accidents (Emergency Planning, Preparedness and Response) Rules, 2019; OISD Standards |

These require fire-rated compartments, blast-resistant control rooms, toxic gas containment. |

VETROGARD® Blast with fire resistance |

|

Oil and Gas Industry |

Fire-rated glass, blast-resistant glass, bullet-resistant glass |

Petroleum and Natural Gas Regulatory Board (PNGRB) guidelines; OISD Standards |

Explosion-proof barriers, blast-resistant control rooms, bullet-resistant glass in critical areas. |

VETROGARD Blast with fire resistance |

|

Petrochemical Industry |

Fire-rated glass, blast-resistant glass |

Factories Act amendments; OISD Standards |

Multi-hazard protection including fire, blast, chemical exposure. |

VETROGARD Blast with fire resistance |

|

Pharmaceutical Industry |

Fire-rated glass, impact-resistant glass |

Drugs and Cosmetics Rules (Ministry of Health); Factories Act |

Sterile clean rooms with fire protection, fire-rated chemical storage, and laboratory safety glazing. |

VETROGARD Attack and blast with fire resistance |

|

Hospitality & Leisure |

Fire-rated glass, fire rated doors |

Local building regulations |

Fire-rated glass in kitchens, laminated and toughened glass in conference and admin areas. |

VETROGARD Attack with fire resistance |

|

Power Generation and Utilities |

Fire-rated glass, blast-resistant glass, impact-resistant glass |

Industrial safety standards |

Boiler rooms, turbine halls, control rooms, electrical switchyards require specialised glazing. |

VETROGARD Blast with fire resistance |

|

Automotive Manufacturing |

Fire-rated glass, chemical-resistant glass, impact-resistant glass |

Factories Act; Relevant industrial safety standards |

Paint booths, welding areas, battery production, testing facilities. |

VETROGARD Attack with fire resistance |

|

Food Processing and Packaging |

Fire-rated glass, impact-resistant glass |

Industry safety standards |

Thermal processing, chemical cleaning, cold storage, and packaging lines require fire-rated and chemically resistant glass. |

VETROGARD Attack with fire resistance |

Why Use Certified Glass in Your Factory

Installing the right glass for safety in factories brings multiple benefits that improve both safety and business operations:

-

Keeps Workers Safe

Toughened or laminated glass prevents injuries by holding together when it breaks. It also acts as a clear barrier between workers and hazardous machines.

-

Helps You Follow the Rules

Certified safety glass helps meet UAE factory safety laws and international norms. It makes inspections smoother with proper documentation and tested systems.

-

Creates Better Working Conditions

Safe glass windows brighten spaces with natural light while reducing risks. They also cut noise and allow safe supervision through transparent partitions.

-

Saves Money Long-Term

Insurance costs drop when safety glass systems are in place. They reduce downtime and protect expensive equipment during accidents.

-

Supports Fire Safety in Factories and Warehouses

Fire-rated glass stops fire from spreading, giving people more time to escape. It helps firefighters act quickly and shields inventory from damage.

-

Keeps Business Running

Glass systems isolate problems, keeping other areas fully operational. They protect critical zones and prevent reputation-damaging accidents.

Choosing the Right Glass for Your Facility

Conduct a Safety Assessment

-

Identify areas most prone to accidents.

-

Review existing safety rules and determine where glass upgrades are needed.

-

Consider industry-specific risks, e.g., chemical versus textile production.

Match Glass Types to Risks

-

Install fire-rated glass near heat or flammable materials to reinforce fire and safety practices.

-

Use impact-resistant glass in high-traffic or heavy machinery areas.

-

Combine laminated and toughened glass where multiple hazards exist.

Work with Professionals

-

Consult experts for selecting glass that meets industrial safety standards.

-

Ensure installation by qualified technicians familiar with industrial applications.

-

Schedule routine maintenance for long-term performance.

Plan for Future Needs

-

Account for expansion or regulatory updates requiring upgraded safety measures.

-

Budget for glass solutions that enhance both safety and operational efficiency.

What's the difference between laminated and toughened glass?

Laminated glass and toughened glass work differently: laminated glass stays in one piece when broken, while toughened glass breaks into small, safe pieces. Both improve factory safety but in different ways.

Can safety glass really prevent workplace accidents?

Yes. Impact resistant glass significantly reduces injuries from broken glass and provides barriers that protect workers from machinery, heat, and chemical hazards. It's a proven part of comprehensive factory safety rules.

How does certified glass help with fire safety?

Fire-rated laminated glass, creates barriers that contain flames and smoke, giving workers time to evacuate. This is essential for fire safety in factories and warehouses where a quick-fire spread could trap people or destroy valuable inventory.

Is certified glass expensive?

While certified impact resistant glass costs more upfront than regular glass, it saves money through reduced insurance premiums, fewer accidents, less downtime, and better regulatory compliance. Most factories find it pays for itself through improved factory safety and operational benefits.