Introduction

Choose the right glass to save energy and optimise comfort on your vessel

It is important to consider the complete ecosystem of a vessel or offshore structure when addressing the topic of energy efficiency. Understanding the climate conditions in the surrounding operational environment is also critical when selecting the best glazing solution. Glass can play a key role in reducing energy costs, specifically with regard to temperature control and weight-saving opportunities. Smart engineering upfront can save costs in the long run. Our innovative, energy-efficient glass solutions can help you achieve your sustainability and cost saving goals!

Do you know the difference between the u-value and the g-factor?

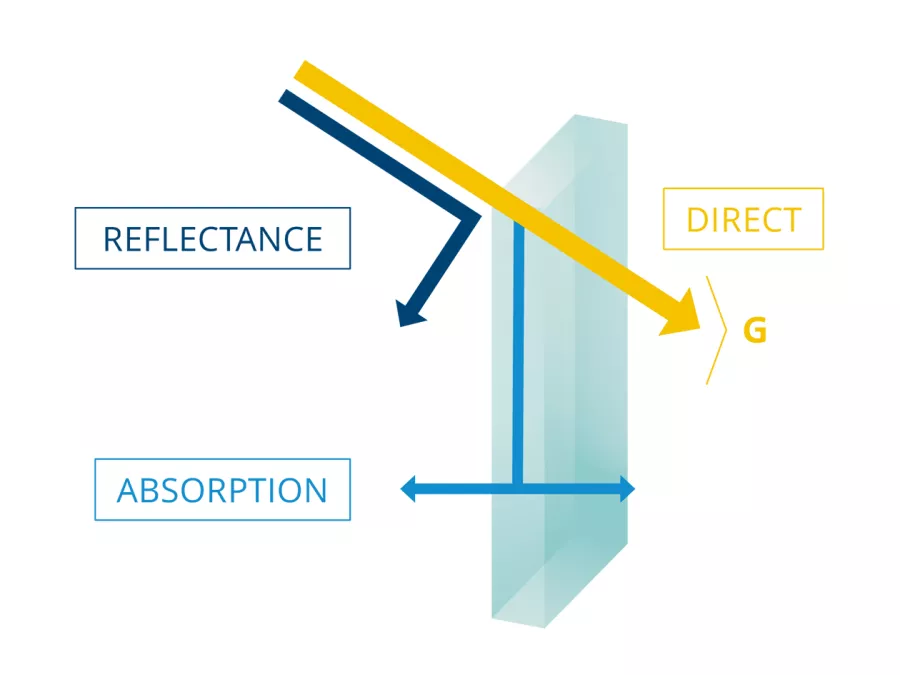

Two important factors to take into consideration before choosing your energy efficient glazing solution are the solar factor (G-factor) and the heat transfer coefficient (U-value). This will enable you to make the right decision based on your operating environment.

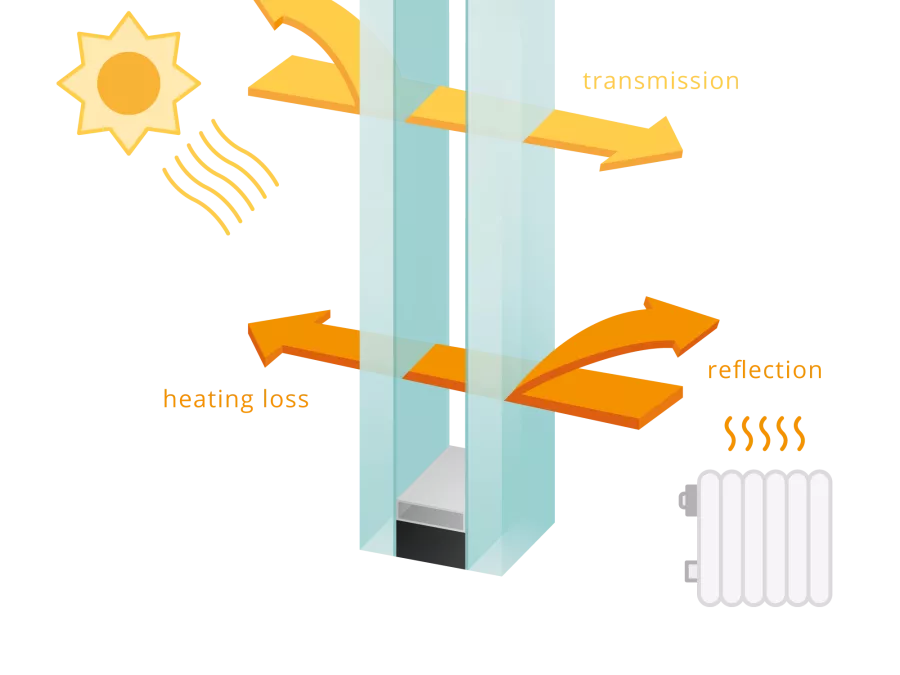

G-value, solar factor

The G-value, or solar factor, is the percentage of total solar radiant heat energy transmitted through glazing (the sum of energy transmitted directly, and energy absorbed and re-emitted to the interior). A smaller G-value is better at reducing heat transfer, because the higher the percentage, the more sun comes in (heat). There are three types of radiation in the solar spectrum:

- rays that can be seen by the naked eye (50%)

- ultraviolet rays (5%)

- and infrared rays (45%)

Ultraviolet and infrared rays are invisible, but all three types of rays emit energy and, therefore, act as heat sources.

An example: glass with a G-value of 42%, allows 42% of solar radiation heat through. Partly directly transmitted and a small part is absorbed by the glass pane. The remaining 58% is reflected to the outside, either directly or through absorption and followed by the re-emission outwards.

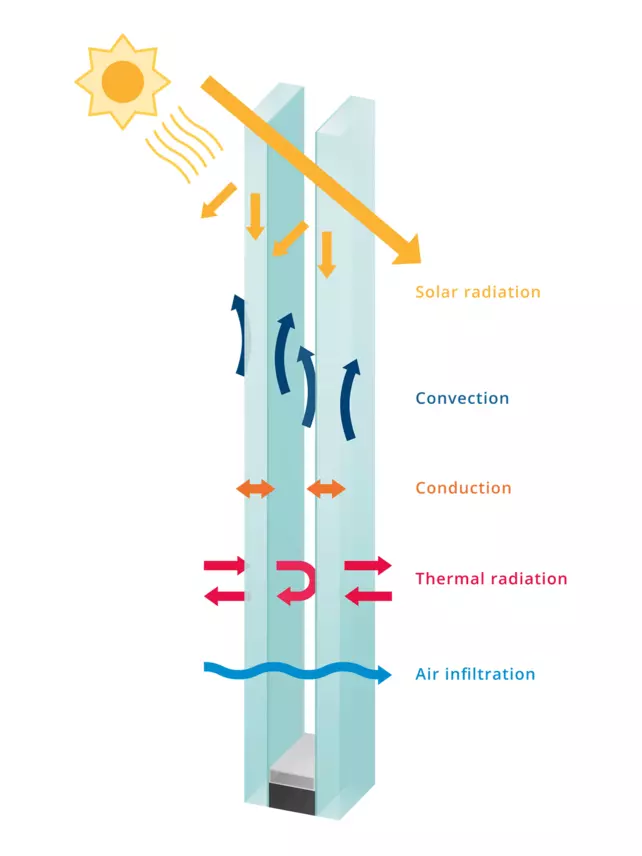

U-value, heat transfer coefficient

The U-value (or K-value), more correctly called the overall heat transfer coefficient, describes how well an element insulates the conduction of heat. It measures the rate of heat transfer through an element over a given area, under standardized conditions. A smaller U-value is better at reducing heat transfer. There are three ways heat can transfer:

1. Conduction

- Heat transfer through a solid, liquid, or gaseous material via molecular contact

- Example: Touching a hot stove

- To reduce conduction in windows, thermal barriers can be added, such as an airspace in a double-glazed unit

2. Convection

- The transfer of heat through the movement of liquids or gases

- Example: Facing into a cold north wind.

- To reduce convection in windows, add enclosed air spaces

3. Radiation

- The transfer of heat through space without relying on an intervening medium

- Example: The heat of the sun on your face.

- To reduce radiation in windows, add low-e coatings.

The U-value can be affected by:

- Glass make-up: monolithic, laminated, insulating or triple insulating

- Coating: non-coated or type of coating

- Spacer: standard steel spacer, aluminum or stainless steel

- Spacer width: range from 12 – 24mm

- Cavity filling: air, argon or krypton gas filling

At vetrotech marine, we know coatings!

Saint-Gobain has been the top glass manufacturer for over 350 years. Vetrotech Marine is the dedicated business unit within this group for high performance marine coatings. We provide a wide range of coatings options, meeting even the most demanding project requirements. We offer optimal passenger comfort on board, while simultaneously having a direct impact on the energy consumption of the ship, maximizing the total cost of ownership.

Combining coatings and insulating glass units for optimal passenger comfort

Cruise ships, ferries and offshore structures are often exposed to the blazing sun from the open seas. In order to keep cabin temperatures at a comfortable and constant temperature, thus reducing the use of HVAC systems, we apply a wide array of coatings to the inner side of double- or triple-glazing units, individually based on customer needs. Our coatings help keep the natural light flowing through our glass surfaces while reflecting or conserving the heat depending on the weather conditions. Choosing the right coating for specific marine needs will help you increase energy efficiency and significantly save costs.

STADIP Lite – weight saving solution

Another way to improve the energy efficiency on board, is through reducing the overall weight of the ship. Discover our light-weight solution STADIP Lite

Find the right balance with CALUMEN® III

CALUMEN® III is a simulation software to calculate key performance of glass such as light transmission, solar factor or thermal insulation coefficient. These values are calculated according to EN410-2011 and EN673-2011 standards. Tolerances are defined according to EN 1096-4 or ISO9050-2003 standards.

While the calculated values cannot be used to guarantee the performance of the product, they can serve as a good reference for determining the required high-performance coating. Our technical experts would be happy to discuss your specific requirements!

Performance

Fire resistance

Fire resistant glass solutions play a key role in preventing the spread of flames, smoke, hot gases and radiant heat, ensuring a safe evacuation.

Energy efficiency

Glass can play a key role in reducing energy costs, specifically with regard to temperature control and weight-saving opportunities.

Weight saving

Our laminated glazing solutions can help you reach your vessel weight requirements by reducing the overall weight contribution.

Heated glass

Vetrotech has been successfully producing heated glass solutions since 1974. The glass, on the one hand, protects people in extreme cold conditions.

Pressure and attack resistance

Whether from a crashing wave or an aggressive pirate attack, glass windows are perceived as a soft spot on a ship. Not with our glass!

Design and comfort

Comfort and design go hand-in-hand in creating an enjoyable atmosphere aboard a vessel. Vetrotech can help you build a welcoming, state-of-the-art vessel with our large choice of innovative comfort.