Burglar resistance of glazed building elements

Date:

But what happens if a burglar decides to attack the glass with a tool other than a hammer or axe?

The EN 1627 standard, which assesses the complete glazing system, defines several resistance levels from RC1 to RC6, with RC1 being the lowest level. In addition, there is a notion of resistance duration, which does not exist in EN356.

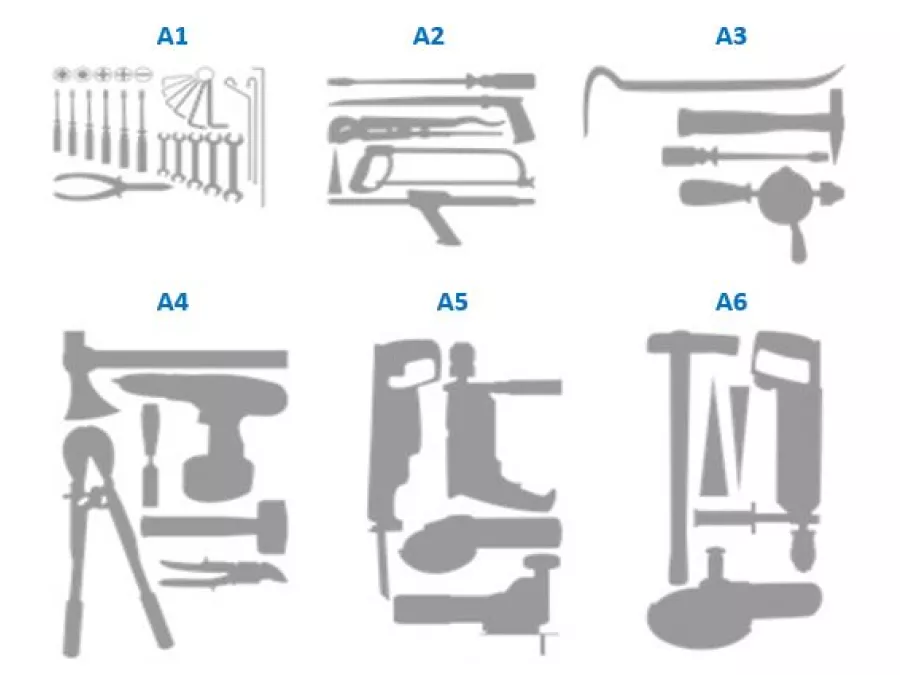

To reach RC1, the glazing system is tested against a whole tool package for a specified time, in this case the A1 package. To reach RC2, it is tested against two tool packages A1 and A2, and always for a certain duration. Each level is therefore more stringent, until the glazing system can resist the following six tool packages.

But there are two problems with this test regime. First, up to and including RC4, it is only the locks and frames that are tested, the glass itself is not touched!

How could regulations be adapted to ensure the reliability of glass solutions?

To ensure optimal safety at each level, we should go beyond current standards and establish tests of all complete systems, including the glazed elements.

Like fire resistance, regulations should then only allow the sale of components that constitute a “complete system” with a Classification Report to certify the reliability of a glazed system, issued by an independent certification body, and following the successful completion of a resistance test of the entire system.

In this way, protection would be enhanced, better protecting both people and property.

Our High security solutions

Whatever your requirements, we’re dedicated to providing multifunctional, high-security glass solutions – for safe, beautiful, sustainable and comfortable buildings.

1 A glazing system consists of several glass panes

2 A "glass solution" or "complete system" consists of glass, a frame and a specific environment. The environment can be, for example, concrete, gypsum, or wood.

3 Vandalism is here defined as an act of unpremeditated destruction. Unlike breaking and entering, it is a spontaneous and improvised act.