Bigger, Faster, More Comfortable: New 4 x 4 m Furnace at IFTS

Date:

IFTS – International Fire Testing + Services

IFTS, a fire resistance laboratory belonging to Vetrotech Saint-Gobain, conducts tests according to all common European and international test standards for building and marine applications. With the new 4 x 4 m test furnace and a high-tech testing environment, 90% of all tests, including type tests, can be conducted at IFTS.

IFTS – International Fire Testing + Services is a subsidiary of Vetrotech Saint-Gobain International AG and is located at the research and development center of Saint-Gobain Germany in Herzogenrath (near Aachen). IFTS is an ISO/IEC 17025 certified testing laboratory accredited by the national accreditation body of the Federal Republic of Germany, DAkkS. It conducts approximately 200 fire resistance tests per year in accordance with the requirements of relevant EN, ISO, BS, UL, ASTM, NFPA, and IMO standards. IFTS collaborates with recognized independent testing and certification bodies (Notified Testing Bodies, NTBs) to review tests, validate results, and issue certificates.

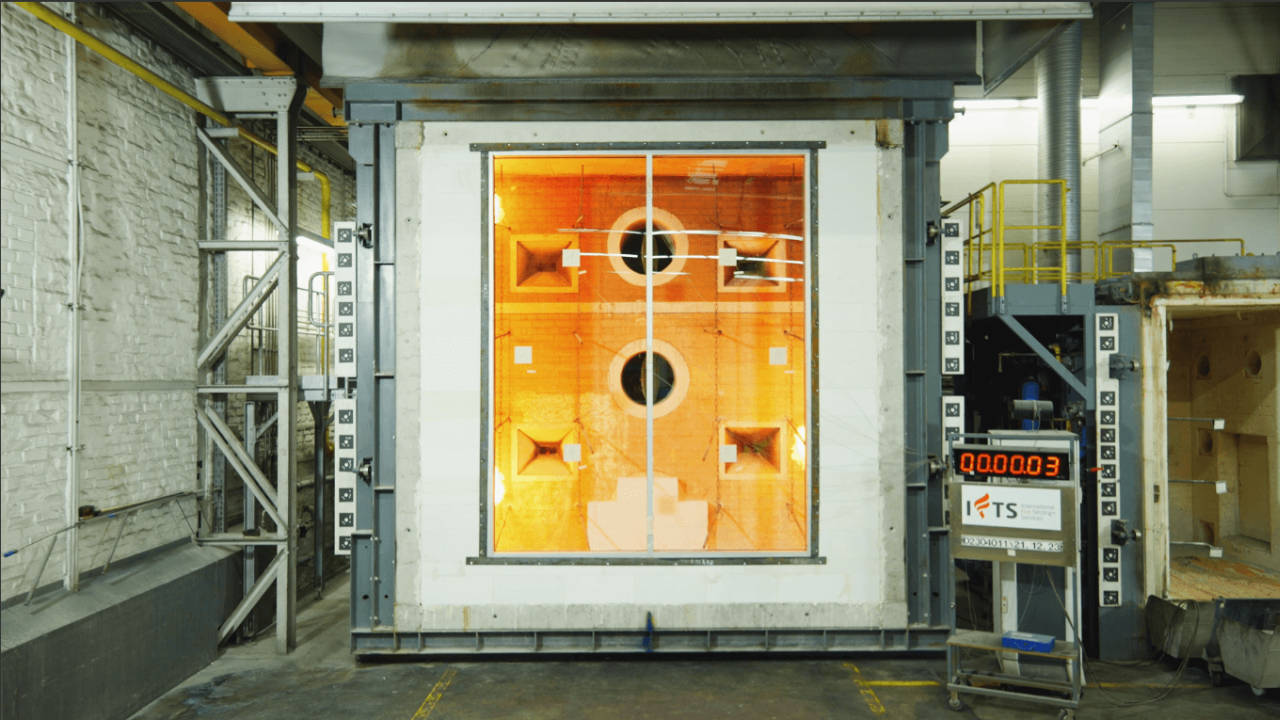

The laboratory has two test furnaces: the medium-sized (1.5 x 2.5 m) "workhorse" for efficient validation of new construction ideas and the new 4 x 4 m test furnace for full-size systems and applications. The large furnace can now be used to test fire protection door applications, including side panels and transom lights, or entire partition walls. Thanks to the modern furnace, customers, supported by the expert team of Vetrotech Saint-Gobain, can accelerate the market launch of new solutions.

High-Tech Monitoring for Safer Tests

The new furnace is video-monitored inside – two furnace cameras allow viewing of the exposed area of the test element during the test without customers having to climb onto a platform behind the furnace and look through the eyepiece. Those present at the test will find a well-equipped, comfortable, safe, and confidential environment. A lounge area and a separate meeting room facilitate personal interaction with partners, experts, and testing staff directly on-site. Customers can also follow the tests live via secure video link from their company location without having to be on-site in Herzogenrath.

Depending on the application area of the building element and the requirements of building regulations, a test lasts between 30 and 120 minutes, during which the temperatures in the test furnace rise to over 1,000° C. Fire protection frame systems made of steel, aluminum, and wood are tested for all common classifications. Only if the fire protection glass in combination with the frame passes the fire test does it meet the highest quality standards and can be used in practice for the tested building element.

For media inquiries or further information, please contact Rico Strüby, Communications Manager ([email protected]).